PRODUCTS CENTER

Lower part feeding (wet) semi-countercurrent magnetic separator

Lower part ore feeding (wet) countercurrent magnetic separator

Lower part feeding (wet) gravity magnetic separator

High-intensity flat plate magnetic separator

Concentrated (dehydrated) magnetic separator

Upper double-deck dry selection machine

Magnetic roller (magnetic pulley)

Upper part feeding (dry) high-speed magnetic separator for powdered ore

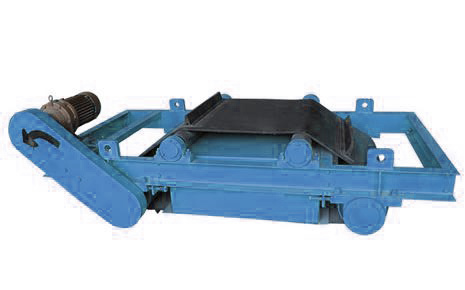

Self-dumping permanent magnetic separator

Upper part ore feeding dry magnetic separator

About Us

Yunnan Feineng Magnetic Electric Technology Co., Ltd. is located in Kunming, Yunnan, a city with beautiful scenery and pleasant climate. It is a large-scale magnetic separator professional manufacturing enterprise in Southwest China, integrating product design, manufacturing and sales, and a mineral processing solution provider. Based on technology, serving the society. Feineng has a technical team with nearly 20 years of experience in the field of magnetic separators, and has established the first magnetic selection technology research and development center in Southwest China in Kunming.

Ten Thousand

Registered Capital

Year

Years of Experience

m²

Modern Plant

Units

Annual Output of Magnetic Separators

The core technical team has 20 years of experience in the design, manufacturing, sales and after-sales service of magnetic separators.

Feineng has large-scale production and manufacturing equipment such as extra-long shear, heavy-duty roll forming machine, automatic milling machine, automatic plasma cutting machine, high-power magnetizer, magnetic block slicer, etc., which can meet the production and manufacturing needs of a wide range of customers for extra-large magnetic separators in the market.

Feineng has a technical team with nearly 20 years of experience in the field of magnetic separators. Through continuous innovation, we have upgraded the manufacturing process of magnetic separators and improved the shearing, rolling, etc., truly achieving refined production of magnetic separators.

Strengthen quality management, improve corporate efficiency; enhance customer confidence and expand market share. Obtain the international trade green card—pass, eliminate trade barriers.

Feineng has its own professional technical team, invests a large amount of funds in R&D every year, and pays attention to quality control and the development of new products.

The company often carries out a variety of collective activities and learning training to improve the overall ability and quality of the team. The purpose of training and learning is to transform the formed overall learning ability into the team awareness and collective wisdom of the enterprise, and continuously increase cohesion and work ability in practice.

Engineering case

after-sale service

Delivery

Feineng has a complete logistics distribution system, and even as few as 1 unit can be delivered point-to-point from the factory to the installation point, fully ensuring the safety and effectiveness of the equipment, and realizing fast logistics services of equipment from leaving the factory to delivery within 2 hours.

Installation and Debugging

The company is equipped with a professional after-sales technical team, which will go to the site for installation and debugging as soon as the equipment arrives. And free on-site teaching and training services for equipment operation and management personnel are provided. Guide quick start, daily equipment maintenance, maintenance.

Maintenance

In addition to regular return visits and maintenance, the company also has a 24-hour standby maintenance team that quickly responds to customer needs and provides customers with quick maintenance services in the first time, providing all-round escort for the service of Feineng magnetic separators, and truly extending the service life of the product for the purpose of persistence and unremitting efforts

Fill in the information and make an online appointment!

Blog