Confused about the different types of magnetic separators? Read this and you'll understand!

2025-03-05

Magnetic separation is the process of separating magnetic materials from other materials using magnetic equipment based on the magnetic properties of the materials. The mechanical equipment used for this operation is called a magnetic separator, which is generally referred to as magnetic separation equipment. Magnetic separation equipment has different classifications from different perspectives. In fact, the names of magnetic separators are named based on various characteristics and standards.

I. Classification by magnetic field strength.

It can be divided into weak magnetic field magnetic separators, medium magnetic field magnetic separators, strong magnetic field magnetic separators, and high gradient magnetic separators.

Weak magnetic field magnetic separators are mainly used for the magnetic separation of strongly magnetic substances, with a specific magnetization coefficient greater than 38 × 10-6 m/kg, such as magnetite, maghemite, titanomagnetite, pyrrhotite, and zinc ferrite spinel and other ferrimagnetic minerals. Weak magnetic field magnetic separators are mainly divided into dry weak magnetic field magnetic separators and wet weak magnetic field magnetic separators. Dry weak magnetic field magnetic separators can also be divided into magnetic roller and permanent magnet roller magnetic separators.

Magnetic field magnetic separators are mainly used for the selection of medium-strong magnetic minerals such as ilmenite and pseudorutile, and the removal of iron from non-metallic minerals. The magnetization coefficient is 1.9 × 10-6 m/kg-38 × 10-6 m/kg.

Strong magnetic field magnetic separators mainly use a closed magnetic system and an induction magnetic pole or magnetic medium of a certain shape to generate a stronger magnetic force in its partition, which can effectively separate weakly magnetic minerals. According to the working form, it can be divided into dry and wet types. The magnetization coefficient of weakly magnetic mineral materials separated by strong magnetic field magnetic separators is less than 1.9 × 10-6 m/kg.

High-gradient magnetic separators improve the magnetic force and processing capacity of the magnetic separator through the interaction between the magnetic medium and the particles, mainly used to solve the separation problem of fine-particle minerals. High-gradient magnetic separators are mainly divided into SLON, YKC, SSS-II, GCG, DCH, ZGCX series.

II. Classification by selection medium.

Magnetic separators are classified into dry magnetic separators and wet magnetic separators.

Dry magnetic separators and wet magnetic separators have different requirements for the moisture content of the material. Dry magnetic separators require low feed moisture content, with the standard being that the material surface is dry, has good fluidity, and does not form adhesion or agglomeration. Wet magnetic separators have requirements for the pulp concentration. There is no obvious limitation on the concentration during rough magnetic separation, but the material concentration should not be too low to effectively control the negative force of the fluid during the beneficiation process, while fine particles and fine-grained materials require a slightly higher concentration to ensure the recovery of magnetic minerals.

III. Classification by magnetic field type.

Magnetic separators can be divided into constant magnetic field magnetic separators, rotating magnetic field magnetic separators, alternating magnetic field magnetic separators, and pulsating magnetic field magnetic separators.

Constant magnetic field magnetic separators use permanent magnetic materials and electromagnets and solenoids as magnetic sources. The magnitude and direction of the magnetic field strength change with time.

Magnetic field magnetic separators use magnets as magnetic sources, and the magnetic poles rotate around the axis, and the magnitude and direction of the magnetic field strength change with time.

Alternating magnetic field magnetic separators use AC electromagnets as magnetic sources, and the magnitude and direction of the magnetic field strength change with time.

Pulsating magnetic field magnetic separators use electromagnets that simultaneously pass direct current and alternating current as magnetic sources. The magnetic field strength changes with time, but the direction remains unchanged.

IV. Classification by magnetic source.

It can be divided into permanent magnet magnetic separators and electromagnetic magnetic separators.

Permanent magnet separators use permanent magnetic materials such as ferrite and neodymium iron boron to generate a working magnetic field, while electromagnetic separators use electromagnets, solenoids, and magnetic conductors to generate a magnetic field.

V. Classification by magnetic system.

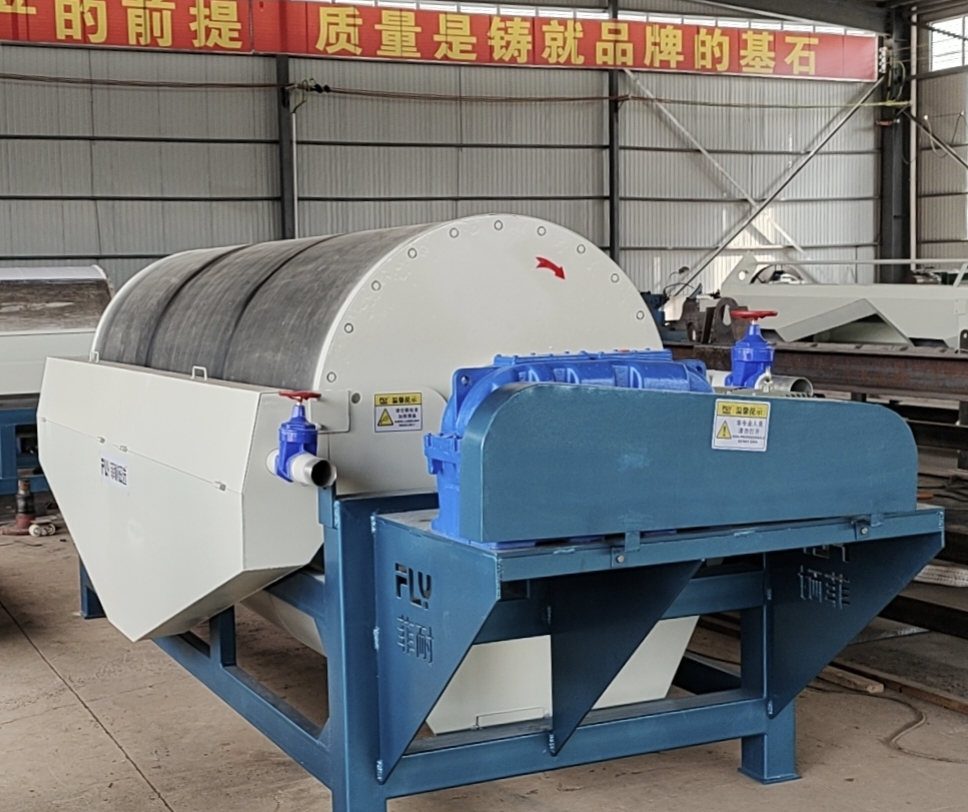

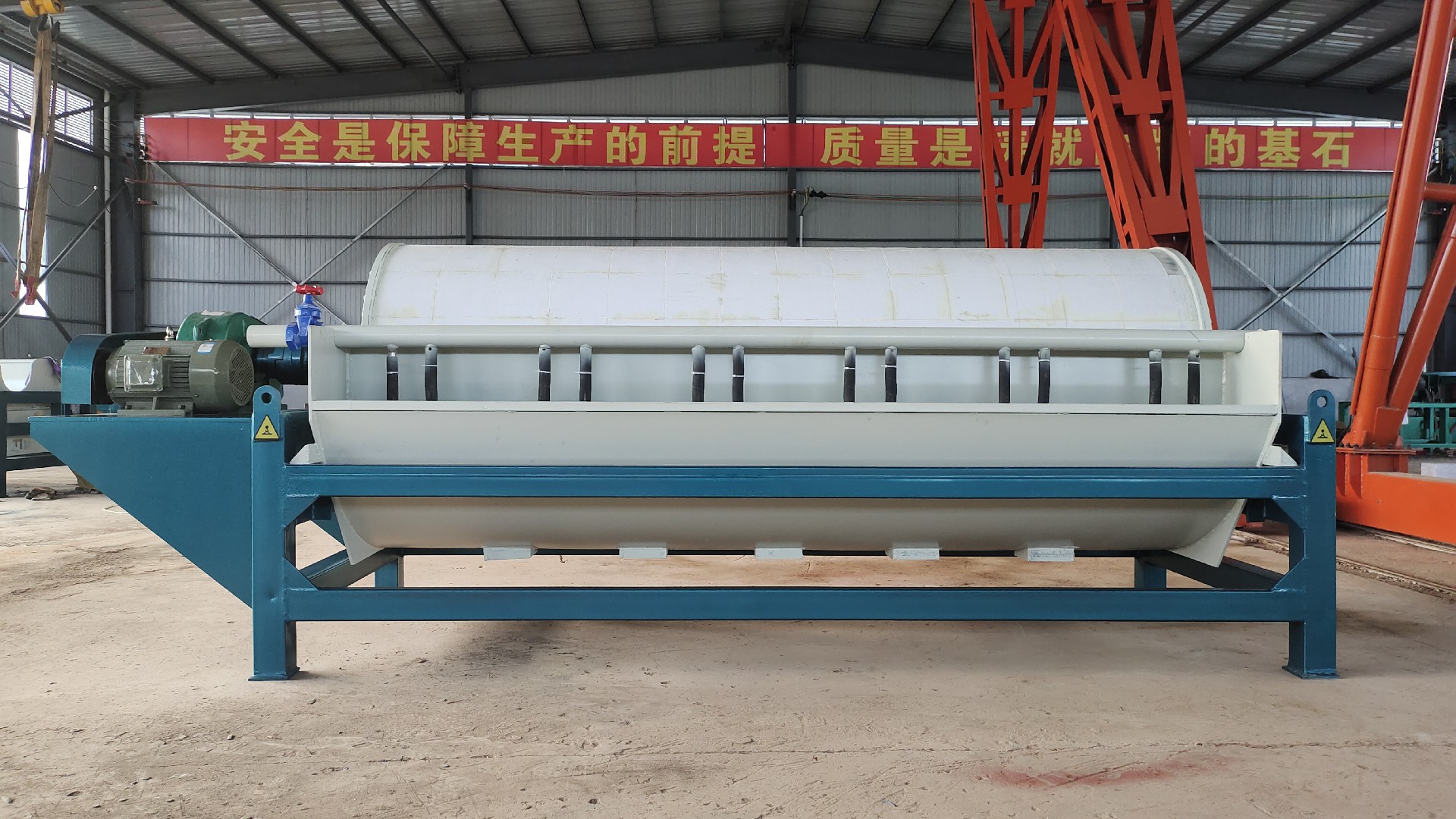

According to the different main structures of the magnetic separator, it can be divided into drum-type magnetic separators, roller-type magnetic separators, disc-type magnetic separators, ring-type magnetic separators, and belt-type magnetic separators, etc.

The drum-type magnetic separator designs the drum as the magnetic separation functional structure, mostly weak magnetic field and medium magnetic field magnetic separators. The outer drum protects the internal magnetic system, so it is called drum-type;

The magnetic separation working surface of the roller-type magnetic separator is completed on the belt-type circular roller, mainly including induction roller-type magnetic separators and permanent magnet roller-type magnetic separators with their own magnetic fields;

The magnetic material of the disc magnetic separator is completed in the separation disc;

The magnetic separation medium of the ring magnetic separator is installed in the ring structure. The ring magnetic separator is developed on the basis of the disc magnetic separator, and its working principle is similar;

The belt-type magnetic separator sends the ore to the uneven magnetic field by belt, and the magnetic induction pole absorbs magnetic particles from the belt and continuously moves to the second magnetic system, forming a continuous discharge of magnetic minerals.

VI. Classification by the number of magnetic systems.

Magnetic separators can be divided into single-drum magnetic separators, double-drum magnetic separators, and combined multi-drum magnetic separators.

VII. Classification according to the movement form of magnetic particles in the magnetic field.

According to the movement form of magnetic particles in the magnetic field, it can be divided into magnetic tumbling machines and non-magnetic tumbling machines.

Magnetic separators are designed for strongly magnetic minerals to be magnetized into magnets in a magnetic field. This type of magnetic separator can effectively improve the grade of the concentrate but may lead to a slight decrease in recovery.

Magnetic separators can be used for the magnetic separation work of strongly magnetic minerals. Although strongly magnetic minerals are magnetized during magnetic separation, the outer cylinder and magnetic system of the unit are fixed on the same bearing, so magnetic flipping will not occur.

VIII. Classification by magnetic structure.

According to the magnetic structure classification, it can be divided into open magnetic magnetic separators and closed magnetic magnetic separators.

Open magnetic circuit magnetic separators refer to magnetic systems where the magnetic poles are adjacent on the same side, and there is no induction magnetic medium opposite the magnetic poles. Since the magnetic flux starts from the N pole, the magnetic flux is dispersed, the air gap magnetic resistance is large, the magnetic field strength is low, and the magnetic field gradient is small.

A closed magnetic separator refers to a magnetic system where the magnetic poles face each other. Various shapes of induced magnetic media are often placed between the magnetic poles, becoming part of the ferromagnetic circuit. This magnetic system may have a single or multiple layers of gaps, but the gaps are small. The magnetic flux is generally linear, with low resistance, concentrated magnetic flux, high magnetic flux density, high magnetic field strength, and large curvature of the induced magnetic pole surface, forming a high magnetic field gradient. Since the magnetic force generated by the magnetic ore is equal to the product of the magnetic field strength and the magnetic field gradient, the strong magnetic field magnetic separation function generates a large magnetic force.

Nine. Classification by the method of selecting magnetic minerals.

They can be divided into extraction-type magnetic separators, suction-type magnetic separators, and attraction-type magnetic separators.

Suction-type magnetic separators generally have better concentrate quality, higher recovery rate, and mainly rely on the gravitational action of the minerals themselves to discharge magnetic products.

Ten. Classification of trough structure types according to the feeding method.

Magnetic separators are classified into co-current magnetic separators, counter-current magnetic separators, and semi-counter-current magnetic separators according to the feeding method and trough structure type.

In a co-current magnetic separator, the mining direction is the same as the rotation deviation of the cylinder (magnetic system). The fed slurry directly enters the bottom of the drum (magnetic system). Non-magnetic and weakly magnetic mineral particles are discharged from the gap between the two bottom plates under the drum, while magnetic mineral particles are adsorbed to the outer surface of the co-current magnetic separator drum and then rotate with the drum to the discharge area, enriching into the concentrate trough.

A counter-current magnetic separator refers to one where the input direction of the slurry is opposite to the rotation angle of the drum. The slurry is directly fed to the bottom of the drum. Non-magnetic and weakly magnetic minerals are discharged from the tailings port on the lower left bottom plate, while magnetic minerals are adsorbed to the cylinder in the opposite direction of the feed, carried to the discharge end, and discharged into the concentrate trough.

A semi-counter-current magnetic separator is between co-current and counter-current. It combines the advantages of both. While obtaining high-grade concentrates, it can also achieve a relatively high recovery rate. Multiple semi-counter-current magnetic separators can be connected in series or parallel, using a multi-scan selection process.

Eleven. Classification by feeding method.

Magnetic separators can be divided into top-feed magnetic separators and bottom-feed magnetic separators.

Previous Page:

Related News

People's Daily, Beijing, March 1 (Reporter Shen Jiaping) According to the official website of the Ministry of Industry and Information Technology, in order to promote the green development of manufacturing, forge new industrial competitive advantages in the process of implementing the carbon peak and carbon neutrality goals, accelerate the construction of a modern industrial system, and promote new industrialization, the Ministry of Industry and Information Technology and six other departments recently issued the "Guiding Opinions on Accelerating the Green Development of Manufacturing" (hereinafter referred to as the "Opinions"), which proposes to focus on the bottleneck links that restrict the green development of emerging industries, accelerate the filling of shortcomings and weaknesses, and focus on solving the sustainable development concerns of emerging industries.

Common malfunctions and solutions for magnetic separators

Are you familiar with the common malfunctions of magnetic separators during daily operation? Below, we will introduce some common magnetic separator malfunctions and quick solutions to address your urgent needs!