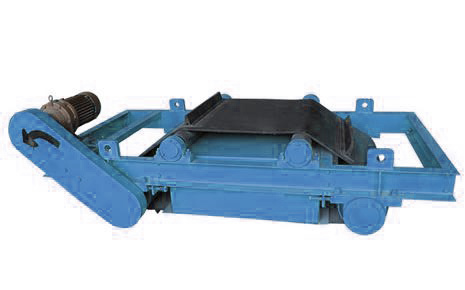

Application Scope

This product is designed for demagnetizing pulp after magnetic separation and before grading and fine screening operations. It breaks down magnetic agglomerates between magnetic mineral particles, eliminating the impact on screening and thus improving beneficiation efficiency and concentrate grade.

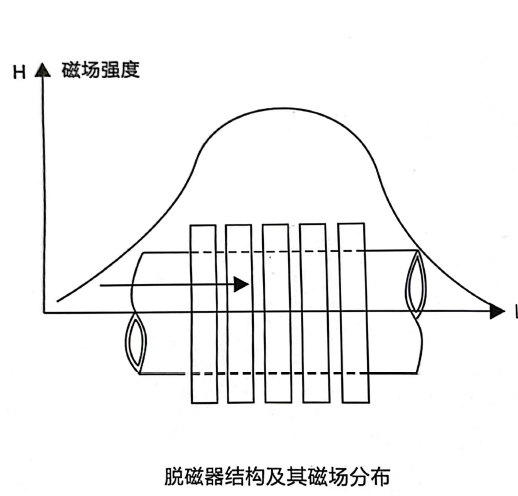

Principle Diagram:

Outstanding Advantages

1. Unlike traditional demagnetizers that use capacitive and inductive attenuation circuits to form discontinuous pulsed magnetic fields, this uses only a single coil and a continuous conical magnetic field. It features low power consumption and high demagnetization efficiency. It is the most effective equipment for beneficiation plants to improve efficiency and concentrate grade.

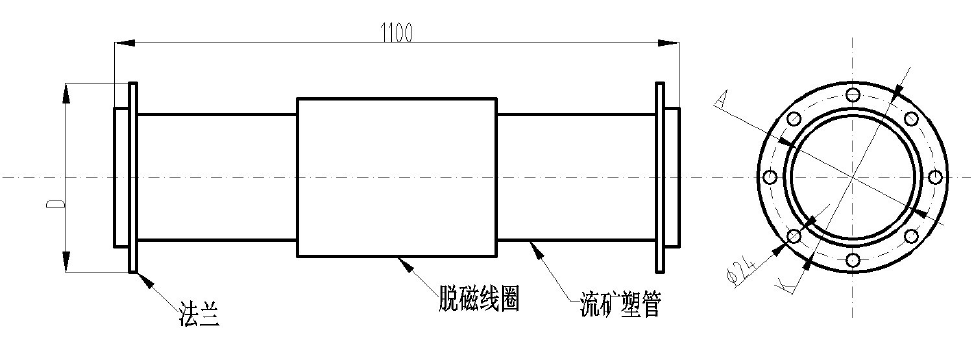

2. The non-magnetic tube, made of special high wear-resistant material, has 3-4 times the wear resistance of stainless steel, greatly increasing the service life of the demagnetizing tube.

3. The magnetic field generated by the coil gradually weakens along the axial direction, alternating at high frequency, causing the slurry flowing along the pipe to be repeatedly magnetized in the positive and negative directions. The residual magnetic induction intensity of strongly magnetic particles gradually weakens until the residual magnetism is completely lost, completing the demagnetization process.

4. In the control circuit, imported IGBT high-power insulated gate bipolar transistors are used as switching control elements for the oscillating circuit, generating a continuous high-frequency alternating current to form a constant high-frequency alternating magnetic field, achieving perfect demagnetization.

5. The voltage waveform in the demagnetizing coil is a rectangular wave, and the current waveform is a high-frequency triangular wave, which can increase the peak value of the oscillating circuit and thus improve the peak magnetic field.

6. The PM module is integrated internally and has self-protection functions such as overcurrent, short circuit, undervoltage, and overheating. It can perform self-shutdown protection under large current surges such as short circuits or other abnormal conditions. This ensures that the control circuit is not damaged and ensures the safe and stable operation of the equipment.

Technical Features

Unlike traditional demagnetizers, it features low power consumption and high demagnetization efficiency. The non-magnetic tube, made of special high wear-resistant material, has 3-4 times the wear resistance of stainless steel, greatly increasing the service life of the demagnetizing tube.

The magnetic field generated by the coil gradually weakens along the axial direction, alternating at high frequency, causing the slurry flowing along the pipe to be repeatedly magnetized in the positive and negative directions. The residual magnetic induction intensity of strongly magnetic particles gradually weakens until the residual magnetism is completely lost, completing the demagnetization process.

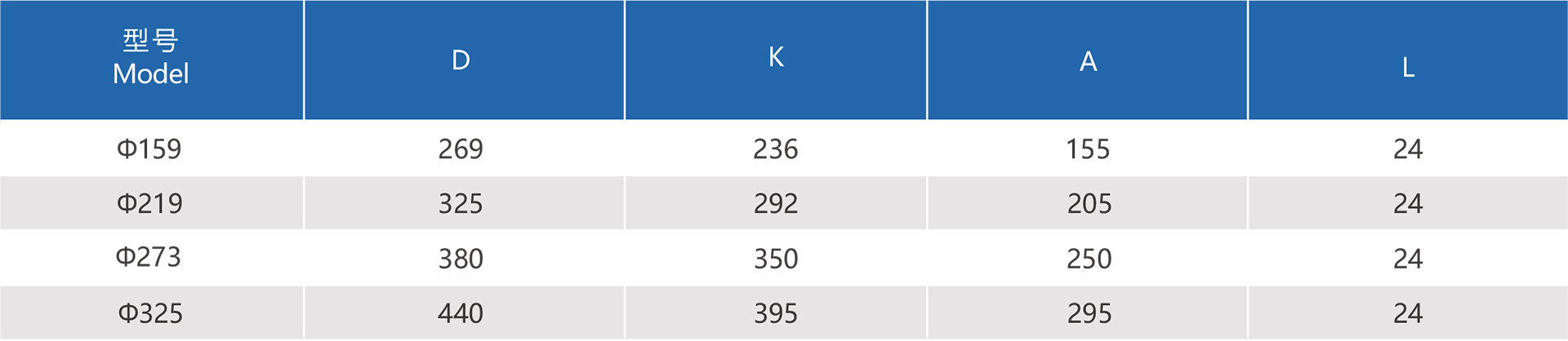

Technical Parameters

Keywords:

Demagnetizer

Contact Us

Category