Scope of Application

Used for rough selection and sweeping operations of strongly magnetic materials with a particle size of 0.6-3mm, as well as primary iron removal from quartz sand.

Technical Features

High recovery rate, suitable for processing coarse materials, focusing on recovery rate and reducing tailings.

This machine can continuously feed and discharge ore, with a strong magnetic field and high magnetic field gradient, resulting in high processing capacity.

The lower feeding wet magnetic separator tank is divided into three types: co-current type (code S), semi-countercurrent type (code B), and countercurrent type (code N). Users can select the appropriate tank according to the ore particle size and required beneficiation index.

Below is a schematic diagram of the working principle of the countercurrent magnetic separator:

Simplified diagram of the wet magnetic separator:

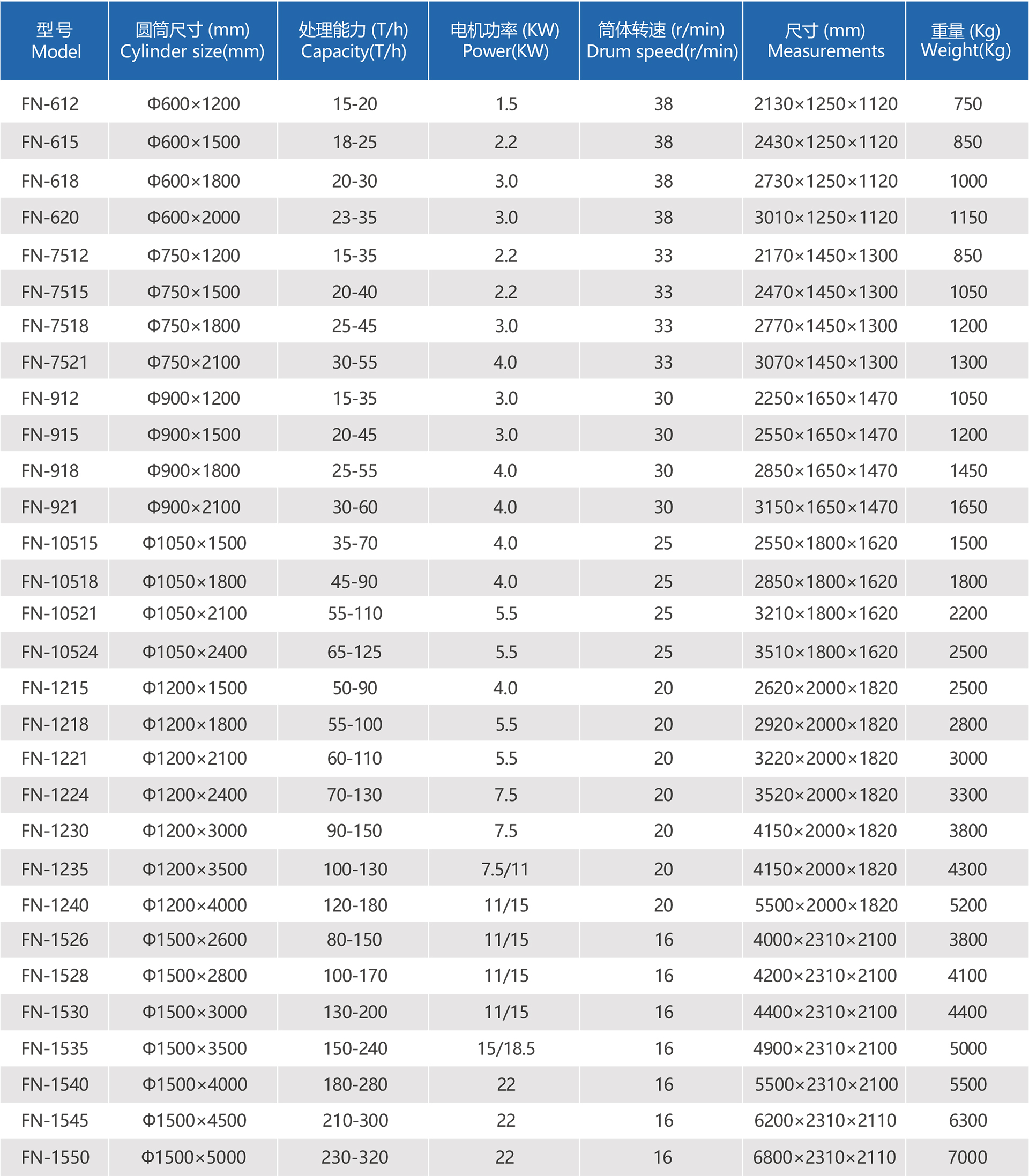

Technical Parameters:

Keywords:

Lower part ore feeding (wet) countercurrent magnetic separator

Contact Us

Category