Scope of Application

The magnetic package angle of this series of magnetic separators is generally 160-175 degrees (special is 180-200 degrees), with a high magnetic field. According to the ore dressing requirements, two magnetic drums can be designed for selection. When the second selection is used as a purification process, the specifications can be slightly smaller than the first one. Many materials can be sorted, such as river sand, sea sand, iron ore, sand and soil ore, dry selection of fine powder materials, dry selection of tailings, dry selection of lean ore, etc.

Technical Features

Clean unloading, high productivity and recovery rate; large processing capacity; particle size is not limited.

Energy saving and environmental protection, improving resource utilization rate, and ensuring work efficiency.

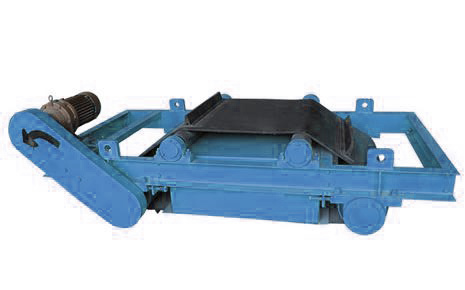

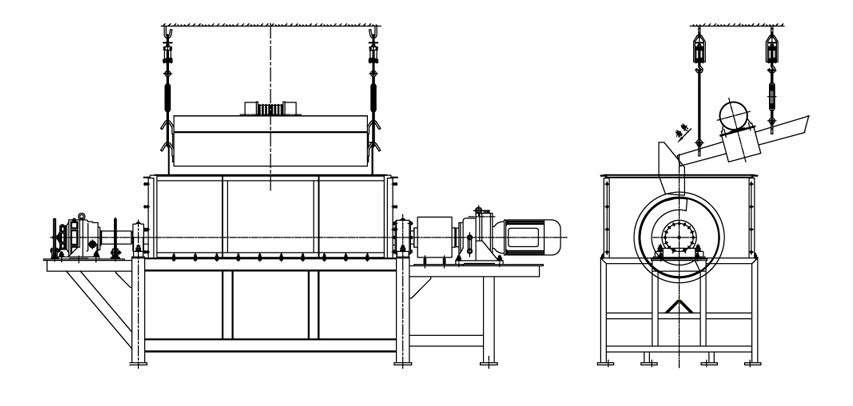

Appearance Diagram

Technical Parameters

Upper part ore feeding dry magnetic separator

Contact Us

Category