Contact Us

Email:

ynfncd@163.com

Phone:

Address:

Yanglin Industrial Park, Songming County, Dianzhong New District, Yunnan Province

Upper double-deck dry selection machine

Double-layer dry magnetic separators are suitable for magnetic separation of materials such as magnetite, pyrrhotite, roasted ore, and ilmenite with a particle size of less than 3mm. They are also used for iron removal in coal, non-metallic minerals, and building materials. The magnetic system uses high-quality ferrite materials or a composite of ferrite and rare earth magnets, resulting in a high average magnetic induction intensity on the drum surface.

Magnetic roller (magnetic pulley)

Mainly used for the primary or secondary crushing of mine ore, followed by the disposal of tailings and sand, as well as purification; purification of low-grade ores; steel slag recovery and iron removal.

Upper part feeding (dry) high-speed magnetic separator for powdered ore

This series of magnetic separators generally has a magnetic package angle of 160-175 degrees (special cases are 180-200 degrees), a high magnetic field, and a high-gradient magnetic field distribution. It can be used to separate river sand, sea sand, iron ore, and sand and soil ore, and can also be used for dry selection of fine powder materials, tailings, and lean ores. The recovery rate is high, reaching over 98%, and the speed is adjustable, allowing for rapid improvement of the ore grade.

This product is designed to demagnetize pulp after magnetic separation and before grading and fine screening operations. This breaks down magnetic agglomerates between magnetic mineral particles, eliminating the impact on screening and thus improving ore dressing efficiency and concentrate grade.

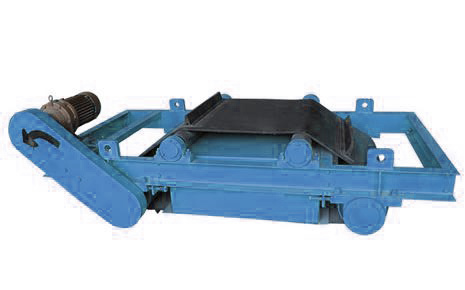

Self-dumping permanent magnetic separator

The FX series self-dumping permanent magnetic separator consists of high-performance permanent magnetic cores, scrap iron belts, reduction motors, frames, rollers, etc., and is used with various conveyors for iron removal in various industries. It can achieve continuous iron removal.

Upper part ore feeding dry magnetic separator

This series of magnetic separators generally has a magnetic package angle of 160-175 degrees (special 180-200 degrees) with a high magnetic field. According to the beneficiation requirements, two magnetic cylinders can be designed for selection, and the specifications of the second selection for purification can be slightly smaller than the first. Many materials can be sorted, such as river sand, sea sand, iron ore, sand and soil ore, dry selection of fine powder materials, dry selection of tailings, dry selection of lean ore, etc.